Concrete Testing Near Me Quality at Your Front Door: Reliable Services

Concrete Testing Near Me Quality at Your Front Door: Reliable Services

Blog Article

Putting Concrete to the Test: Unveiling the Secrets of Product Toughness

Despite its extensive usage, the tricks of concrete's remarkable stamina remain mainly concealed. In this discussion, we will certainly dig right into the composition of concrete, the aspects that affect its strength, and the sophisticated techniques utilized to measure and improve its efficiency.

The Composition of Concrete

Concrete is a composite material being composed of a mixture of cement, water, accumulations, and frequently various other ingredients. This mix offers concrete with its special homes, consisting of resilience, flexibility, and stamina. Concrete, which works as the binder, is usually made from limestone, clay, or shale that has actually been finely ground and afterwards heated to high temperatures in a kiln. The resulting powder, called Portland cement, reacts with water to form a paste that hardens and binds the accumulations together.

Accumulations, such as sand, crushed rock, or crushed rock, comprise the bulk of the concrete combination. They provide toughness to the product and fill up the spaces in between the cement particles. The shapes and size of the accumulations can affect the workability and stamina of the concrete. Additionally, various other additives might be included in the mixture to boost particular buildings or address particular demands. These ingredients can improve the workability, minimize the water material, boost the stamina, or improve the durability of the concrete.

Recognizing the composition of concrete is critical for engineers and building and construction experts to make and build frameworks that fulfill particular efficiency needs. By thoroughly picking the type and percentage of each component, the wanted strength and toughness of the concrete can be achieved. Furthermore, improvements in material scientific research remain to discover brand-new ingredients and combinations that can even more improve the properties of concrete, making it a much more flexible and trusted building product.

Aspects Influencing Concrete Toughness

Different kinds of concrete have varying chemical structures, which can affect the strength of the resulting concrete. In addition, the dimension and shape of accumulations made use of in the mix can influence concrete stamina.

Other factors that influence concrete toughness consist of making use of admixtures, such as accelerators or plasticizers, the enhancement of extra cementitious materials, and the presence of contaminations or impurities in the raw materials.

Testing Approaches for Concrete Stamina

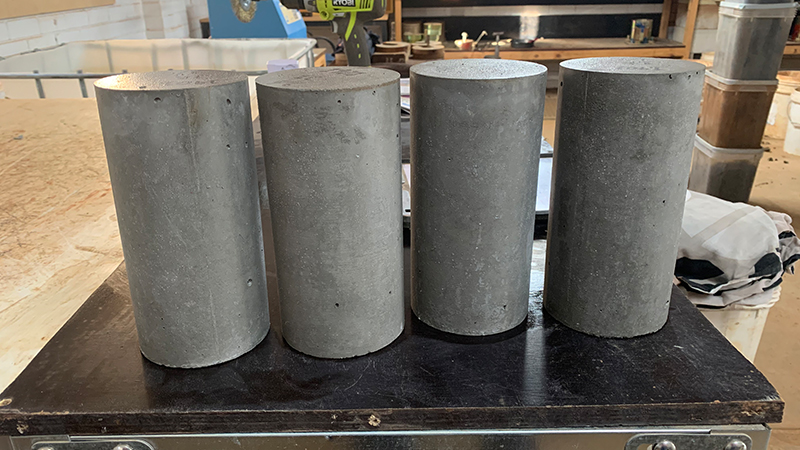

One commonly made use of technique for evaluating the stamina of concrete is via the application of various screening techniques. One of the most commonly made use of techniques is the compressive stamina examination, which measures the maximum tons a concrete example can endure prior to it falls short.

Another crucial screening method is the flexural stamina examination, which evaluates the ability of concrete to resist flexing forces. This examination entails subjecting a beam-shaped concrete specimen to a slowly boosting lots until it reaches its maximum bending capability. By gauging the load and deflection at failure, engineers can figure out the flexural toughness of the concrete.

In enhancement to these tests, there are other methods offered for analyzing concrete strength, such as the split tensile strength test, sites the pull-off test, and the ultrasonic pulse speed examination. The split tensile stamina examination gauges the capacity of concrete to stand up to tensile pressures, while the pull-off examination reviews the bond stamina in between the concrete and other products. The ultrasonic pulse speed examination uses sound waves to establish the top quality and harmony of concrete.

Enhancing Concrete Sturdiness

To further optimize the durability and resilience of concrete frameworks, numerous strategies can be utilized. One approach is to use top notch materials during the concrete manufacturing process. This includes thoroughly selecting accumulations, concrete, and additives that improve the toughness of the last product. concrete testing near me. For example, using well-graded accumulations with correct bit size distribution can enhance the general stamina and resistance to cracking. In addition, integrating supplemental cementitious materials such as fly ash or slag can boost the concrete's resistance to chemical assault and reduce leaks in the structure.

Additionally, effective healing methods play a crucial duty in enhancing concrete longevity. Healing involves keeping adequate dampness and temperature problems for the concrete to effectively moisturize and gain stamina. This procedure helps stop cracking, surface area issues, and enhances total resilience.

Future Technologies in Concrete Innovation

In the world of concrete technology, improvements imminent guarantee to reinvent the industry and redefine the possibilities of building and construction. Scientists and engineers are frequently making every effort to establish innovative techniques and products that can boost the performance and sustainability of concrete.

One of the future advancements in concrete modern technology is the use of self-healing concrete. This innovative innovation allows concrete to fix itself when cracks occur. Microorganisms embedded in the concrete are activated upon fracture formation, creating sedimentary rock to fill the spaces and bring back the structural stability of the material. This not only enhances the life expectancy of concrete frameworks however likewise minimizes the requirement for costly repair work and maintenance.

One more area of development is the usage of nanotechnology in concrete manufacturing. Nanomaterials, such as carbon nanotubes and graphene, can be included to concrete to improve its mechanical buildings. These products have high stamina and conductivity, improving the resilience site link and performance of the concrete - concrete testing near me. In addition, nanotechnology can be used to create self-cleaning concrete, which minimizes the requirement for regular maintenance and cleansing.

Furthermore, researchers are exploring making use of 3D printing innovation in concrete building. This technique permits the accurate and reliable construction of complex frameworks, reducing product waste and building and construction time. It likewise opens new opportunities for architectural style and customization.

These future advancements in concrete technology have the prospective to revolutionize the building sector, making it extra sustainable, reliable, and cost-effective. With continuous study and development, we can anticipate to see these advancements end up being a fact in the future.

Conclusion

Finally, recognizing the composition of concrete and the variables that affect its toughness is crucial for improving its durability. Various testing techniques can be used to accurately measure concrete stamina, supplying beneficial insights for building and construction projects. As innovation continues to development, future technologies in concrete technology hold the potential to even more improve the stamina and toughness of this crucial construction material.

In enhancement to these examinations, there are other techniques offered for analyzing concrete strength, such as the split tensile strength test, the pull-off examination, and the ultrasonic pulse rate examination. The split tensile toughness test measures the capability of concrete to stand up to tensile pressures, while the pull-off examination assesses the bond stamina between the concrete and other products.One of the future advancements in concrete innovation is the usage of self-healing concrete. These materials have high toughness and conductivity, improving the durability and performance of the concrete. As innovation proceeds to development, future technologies in concrete modern technology hold the possible to additionally improve the strength and Visit This Link resilience of this vital building material.

Report this page